There are as many different ideas as people when it comes to how to best seal an RV!

I have used Dicor for many different RV and never had to revisit the spots. However, it is true that new sealants will often not stick to old sealants. New silicone will not stick to old!

This is true of sealing Rv or sealing aquariums. I have more experience with sealing tanks but the process is the same for me.

First step is to be sure you are working on the correct spot as water can be very tricky in the way it runs generally down but may take a very complex route to get to the spot it comes inside for you to see!

One way to feel better about getting the correct leak sealed is to do ALL ot the seals near that spot! That will take far more time, far more effort but also can avoid the damage of missing the right spot!

I look at what is there first. If there is a big gob or layer of sealant of any type, I remove it and clean the spot super well. One of the oscillating tools with a flat blade is one I find super for removing caulk/sealants with too much work or gouging the material. Rubbing alcohol or minerals spirits does it for me with lots of scrubbing and using new rags.

Then I try to "think like a raindrop"! How will water in that specific spot move, when setting or driving?

I watch those lights very carefully as they are a real suspect! I usually take them off and start from scratch on them, sealling both around the holes where the wires go in, just in a circle and then after putting the light back, I also seal in a tiny thin line around the edges. Double seals? Yes, becasue I know they are famous for leaking and the outer seal gets weather and goes bad before the innner seal which is out of the weather abuse!

You will likely find lots of sealant but keep in mind that more is not often better if it forms some type of "lip" around things like vents and the lip can hold water to set there long enough to find a way in. I want all seals to taper to let water run downhill and away!

But you will find a really wide range of differing opinions on sealing and mine is simple one that I use, not necessarilly the only way that works.

What you may read on "expert" websites? Those are actually written by people who depend on lots of traffic to may them money. They are often not REAL experts but just folks like us who will pass on what they may have read, whether they have ever done the job or not!

Getting a firm consistant answer? Not going to happen!

I'm more in tune with the slide question! I can give you pictures from online and I trust that far more than ideas on sealing!!

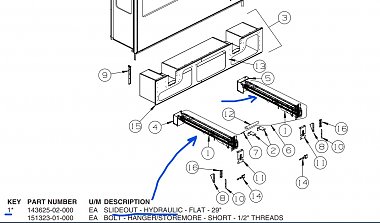

You have hydraulic rams which move the slide as shown here.

This drawing set, on sheet 76 shows the pump involved in jacks and slides:

https://www.winnebago.com/Files/File...04/4ifg33v.pdf

Those hydraulic rams have tubing /lines which run back to a hydraulic pump under the RV and likely work off the same hydraulic pump as the other slide and jacks.

The pump tank and fluid are all common. But at each line going to all the different places the pressure is used, there are control solenoids. The pump running makes super high pressure and when the correct solenoid opens, that pressure goes to the lines and to the correct ram or jack to move things.

The solenoid is just a valve (switch?) which is opened by the electrical signal which starts at the slide or jack controls.

Think of it as an electrically operated gate for the pressure? Pump builds pressure when it runs and solenoid opens the gate when it gets the signal from your switch!

In your case, if all the other items like jacks and other slide are working, there is likely a problem in gettting the specific solenoids opened to let pressure run to the rams for this slide!

The possible items to check are that the electrical switch is working right to pass the word to the solenoid. That seems okay if it works after a time but it "could " be an intermitant switch? It "could" be a loose wire?

More suspect might be the solenoid on the pump is sticky and not opening when it gets the signal. That can need some good info on which brand, model, etc. pump you have and then locate which solenoid works for which line going to that slide. First checking that the 12VDC signal gets from the switch inside to the solenoid?

As I read it, changing a solenoid is not all that complex but I also admit to never having done it!

Others will have better info on that idea.